| Product used | Application | Characteristics | Advantage |

|---|---|---|---|

Savetix® washer and Savetix® screw as a set |

After fitting, the Savetix® washer is held by the thinner part of the screw shaft, but is fully movable. | Since the screw has considerable freedom of movement, this version is recommended where a machine requires frequent maintenance. |

|

Self adhesive Savetix® washer and Savetix® screw as a self-adhesive set |

As above, but with self-adhesive washers. | As above. 3, but this set simplifies simultaneous fitting of many screws. Improves convenience and safety during installation. |

|

| Description | This glue is a modified, solvent-free acrylate adhesive. It has excellent tack and instantly adheres well to most surfaces including such difficult surfaces as foam and PE or PP film. The glue is free of APEOs. | |

|---|---|---|

| Technical data | Backing material | Nonwoven fabric 12 g/m2 |

| Cover | Release paper, yellow, 90 g/m2 | |

| Glue application weight | 90 g/m2 | |

| Total thickness | 0,10 mm | |

| Adhesive strength | min. 16 N / 25 mm2 (contact time: 1 h) | |

| Temperature resistance | from – 40°C to +100°C | |

|

||||||

| Size (nominal size) |

Diameter of hole d1 | Outer diameter D2 | Thickness s nominal size |

Height b max. |

Contact area c | Material |

|---|---|---|---|---|---|---|

| M4 | 4,1 | 19,5 | 0,4 | 3,8 | 2,7 | A2 |

| M5 | 5,1 | 20,5 | 0,5 | 4 | 2,7 | |

| M6 | 6,1 | 21,5 | 0,6 | 4,2 | 2,7 | |

| M8 | 8,1 | 25 | 0,8 | 5,4 | 2,7 | |

| M10 | 10,1 | 27,5 | 1,0 | 5,8 | 2,7 | |

| M12 | 12,1 | 29,5 | 1,2 | 6,5 | 2,7 | |

Standard tolerances to to DIN 6930

Savetix® washers is also available in special, customer specific sizes.

|

|||||

| Size (nominal size) d |

Spanner size s |

Head height k |

Length l |

Threaded length b1 |

Material |

|---|---|---|---|---|---|

| M4 | 7 | 2,8 | The following lengths are available: 6, 8, 10, 12, 14, 16, 20, 25, 30, 35, 40, 45 mm (length depends on size) |

To customer specification min. 4 mm |

A2 |

| M5 | 8 | 3,5 | |||

| M6 | 10 | 4,0 | |||

| M8 | 13 | 5,3 | |||

| M10 | 17 | 6,4 | |||

| M12 | 19 | 7,5 | |||

|

||||||

| Size (nominal size) d |

Spanner size s |

dk | Head height k |

Length l |

Threaded length b1 |

Material |

|---|---|---|---|---|---|---|

| M4 | 3 | 7 | 4 | The following lengths are available: 6, 8, 10, 12, 14, 16, 20, 25, 30, 35, 40, 45 mm (length depends on size) |

To customer specification min. 4 mm |

A2 |

| M5 | 4 | 8,5 | 5 | |||

| M6 | 5 | 10 | 6 | |||

| M8 | 6 | 13 | 8 | |||

| M10 | 8 | 16 | 10 | |||

| M12 | 10 | 18 | 12 | |||

| Position / angle | Torque | |||||

|---|---|---|---|---|---|---|

| M4 | M5 | M6 | M8 | M10 | M12 | |

| 1 (90°) | 0,75 | 0,914 | 0,984 | 2,092 | 6,842 | 11,546 |

| 2 (180°) | 0,848 | 1,702 | 2,082 | 3,594 | 12,2 | 26,63 |

| 3 (270°) | 0,978 | 2,326 | 2,89 | 5,558 | 13,05 | 29,146 |

| 4 (360°) | 1,12 | 2,396 | 3,384 | 6,754 | 13,368 | 30,008 |

| 5 (450°) | 1,22 | 2,406 | 3,614 | 7,286 | 13,444 | 30,042 |

| 6 (540°) | 1,25 | 2,406 | 3,756 | 7,398 | 13,444 | 30,132 |

| 7 (630°) | 1,234 | 2,452 | 3,76 | 7,756 | 13,626 | 30,132 |

| 8 (720°) | 1,26 | 2,504 | 3,768 | 8,228 | 13,662 | 33,644 |

| 9 (810°) | 1,594 | 2,504 | 4,012 | 9,2 | 25,112 | 55,384 |

| 10 (900°) | 2,02 | 3,2 | 4,53 | 11,754 | ||

| 11 (990°) | 2,132 | 3,514 | 6,36 | 14,798 | ||

| 12 (1080°) | 2,186 | 3,878 | ||||

| 13 (1170°) | 2,4 | |||||

| 14 (1260°) | 2,606 | |||||

First put the screw through a flathead washer (if you are using one) and insert it through the protective guard you want to attach. Then put the Savetix® washer onto the screw from behind and screw the protective guard into position on the housing or frame.

The Savetix® washer gets flattened during this process, making the hole smaller than the diameter of the threaded part of the thin-shank screw.

This deformation means that Savetix® has reduced the inner radius of the screw-hole so that the threaded part of the screw cannot fit back through the hole in the Savetix® washer or the protective guard.

Download instruction 'The best way to attach things with Savetix®' (PDF format)

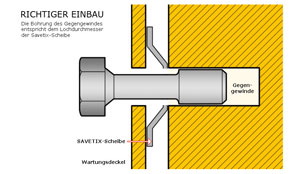

Proper installation:

The bore of the mating thread corresponds to the diameter of the hole Savetix disc.